[SBM]Bolt Measurement Machine

Creates a Brand New Inspection Era

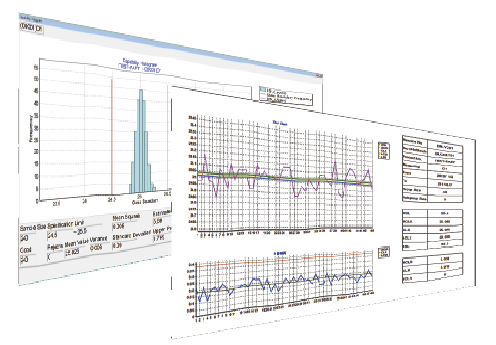

SBM-35L is specially designed for quick inspection purpose of bolt products during the manufacturing process so that quality control can be implemented on each manufacturing process. The measurement data obtained from each process can be utilized for complete process capability analysis and failure tracing.

Simple and Quick Measurement (Part of the screen under development)

STEP 1 Set product

STEP 2 Select Spec

STEP 3 Press Start

Measurement Completed !

↓ ↓ ↓

Inspection results can be uploaded to database for statistical and process capability analysis Inspection results can

Traditional measurement methods

Traditional measurement will create disputes due to different personal judgments

Expensive and highly occupied

Unutilized capacity caused by waiting line

Radius can`t be easily inspected, prone to error

Paper records are difficult to manage and use

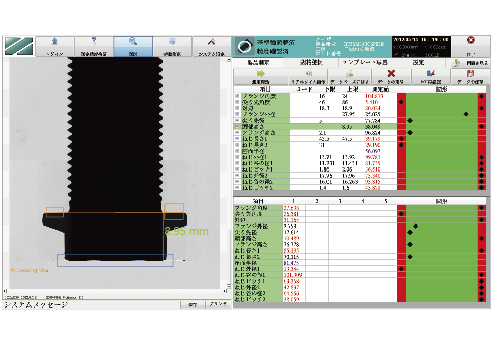

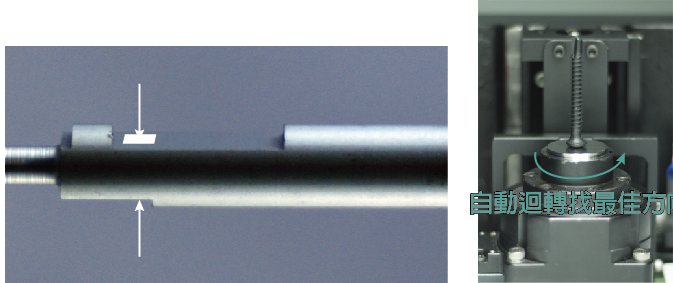

Automatic Capturing of Best Measurement Angle

|

For the dimension marked below, part rotation are required to measure the correct dimension

|

Flexible Measurement Functions

Distance

Set point, line, axis to measure the distance in between

Set point, line, axis to measure the distance in between

Radius

Radius of head, bearing surface and tail

Radius of head, bearing surface and tail

Thread

Use the built-in inspection program to facilitate the thread measurement

Use the built-in inspection program to facilitate the thread measurement

Angle

Estimate the angle between two lines to measure the various angles quickly

Estimate the angle between two lines to measure the various angles quickly

Bearing Diameter

Simplify the difficult measurement on bearing surface

Simplify the difficult measurement on bearing surface

Rotation Function

Extend the measurement functions such as A/F & A/C of the hexagon screw, initial distance of thread, etc...

Extend the measurement functions such as A/F & A/C of the hexagon screw, initial distance of thread, etc...

Geometric Tolerance

| Products | |

| Nuts | |

| Bolts | |

| Washer | |

| Toolings | |

| Machinery | |

| ---[SNF-P]Precision Series Nut Former | |

| ---[SNF-B]Basic Series Nut Former | |

| ---[SBF]Bolt Former | |

| ---[SNT]4 Spindles Nut Tapping Machine | |

| ---[SNT-D]Round Nut Tapping Machine | |

| ---[SNT-W]High Precision Tapping Machine | |

| ---[SNS]Optical Nut & Bolt Sorting Machine | |

| ---[SBM]Bolt Measurement Machine | |

| ---[SNA]Nylon Insert Assembly Machine | |

.png)